Our scope

Kriosystem’s input into the project included the delivery of multichannel cryogenic transfer lines, large-size superfluid helium cryostat, and auxiliary cryogenic transfer systems. The infrastructure is primarily used for testing superconductive RF cavities at -271°C, which are essential components of the XFEL accelerator.

The scope of the delivery covered manufacturing and testing, including notification body certification, on-site installation, and final test. The project was made in cooperation with Wroclaw University of Science and Technology and Wroclaw Technology Park.

CRYOSTAT

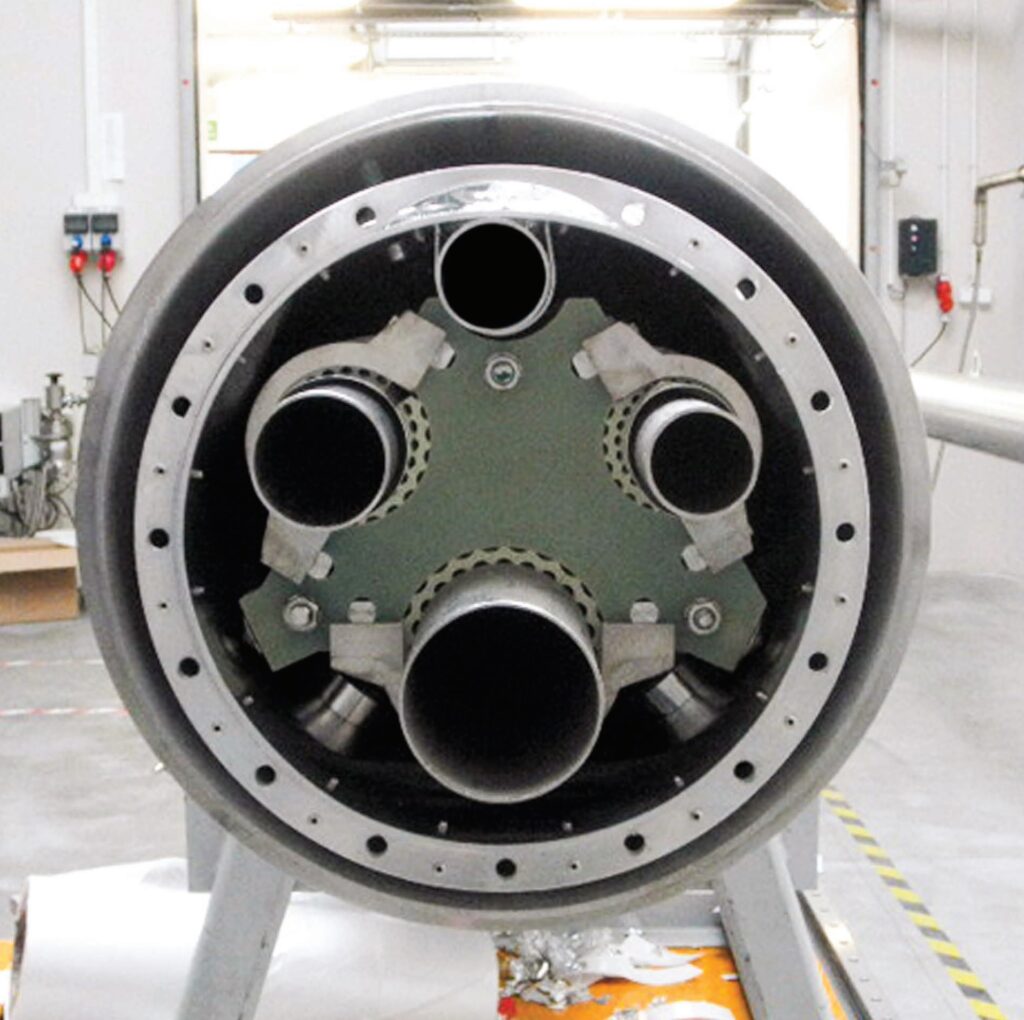

SUPERFLUID helium cryostats XATC consist of an internal helium pressure vessel encompassed by a copper thermal shield and vacuum vessel. In the helium vessel specially designed insert is placed from the top to support four RF cavities. Additionally, in order to perform tests under superfluid helium conditions, a unique heat exchanger was developed.

The cryostat is 4,5m high and its diameter equals 2m, while the total weight is 4,5 tonnes. It is equipped with cryogenic valves, TVO-type temperature sensors, pressure sensors, and level sensors. All cryostats are installed with a complete pressure safety system.

XATL1

Multichannel transfer line XATL1 comprises four process pipes encompassed by an aluminum thermal shield and vacuum jacket. Line, which total length equals 167 m, is composed of 15 sections, both straight and elbow ones. The largest process pipe diameter is DN80 and the vacuum jacket size is DN400. The line is located on the pipe bridge, which connects the liquefaction unit with the test bench.