Vacuum Insulated Piping

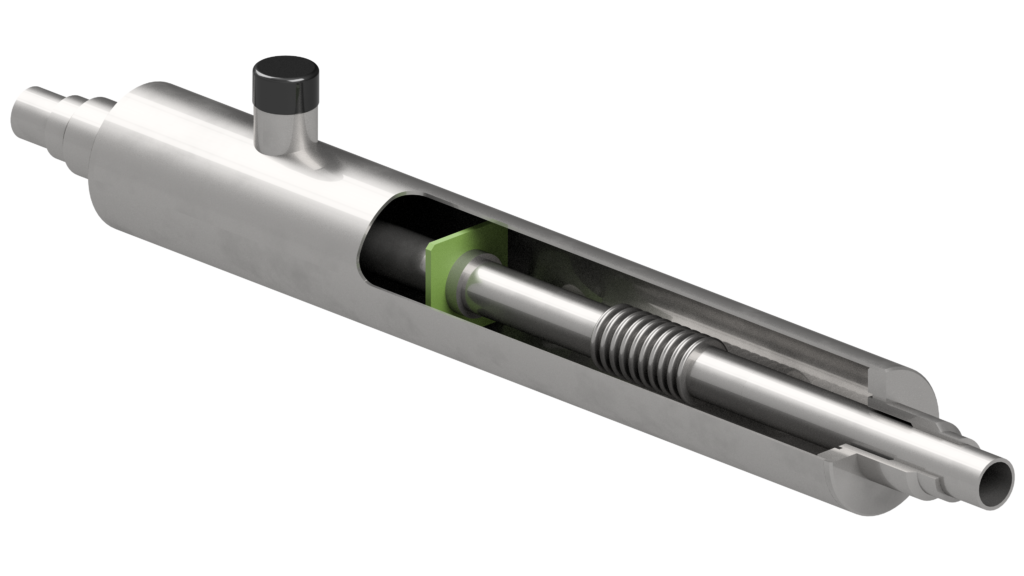

VIP (Vacuum Insulated Piping) is commonly used for transferring liquefied technical gases and LNG. Its design includes:

- process (inner) pipe in which flow of the medium takes place

- vacuum (outer) jacket, which provides leak-tightness for vacuum

- cryogenic multilayer insulation

- insulating spacers

- moisture adsorption sorbent

- thermal compensation elements

The vacuum in the outer jacket reaches 10-4 mbar. Therefore, VIP accommodates minimum cryogen losses with its small dimensions. Heat load is as low as a single Watt per 1 m of piping. Our design including vacuum & MLI insulation is the most effective commercially available solution on today’s market. The thermal conductivity of the MLI vacuum insulation is several times lower than commercially available PUR-type foams. For as thick as 80 cm foam insulation of the liquid nitrogen pipe, the heat load (and gas evaporation losses) is still much bigger than for MLI vacuum insulation.

VIP is prefabricated as sections of appropriate shapes and lengths, which can be further connected with each other by means of:

- bayonet connection: detachable joints, easy to assemble and disassemble

- muffs: welded joints that guarantee high leak-tightness of the system