When to use vacuum-insulated piping?

VIP pipelines are used to transport cryogenic liquids. Their technology allows the reduction of fluid losses (up to 20 times lower losses compared to traditionally insulated systems) while maintaining a small size. VIP pipelines offer the best return on investment, as they have the highest performance and longest life cycle.

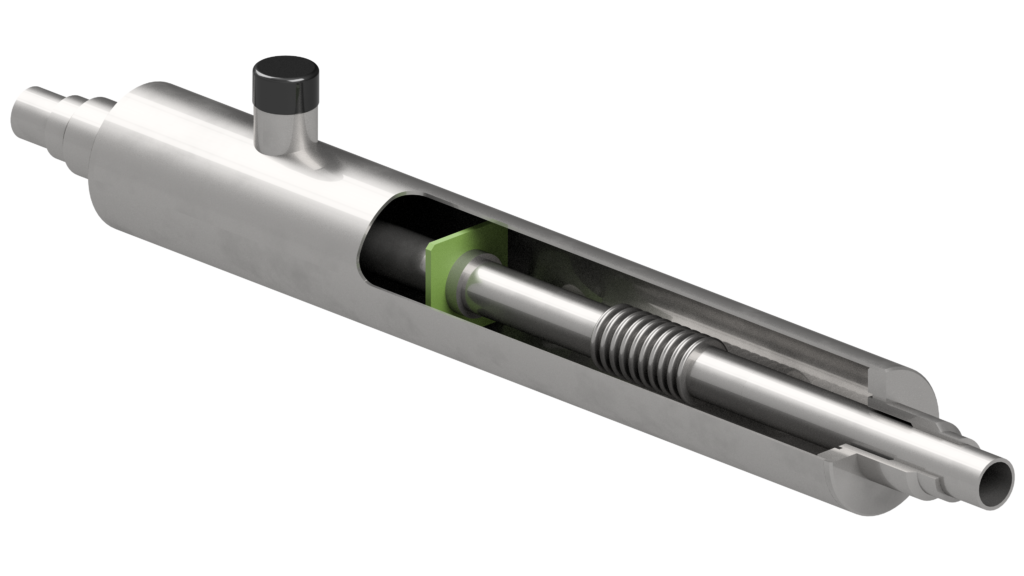

VIP pipelines consist of:

- process pipeline (internal) in which the gas flows

- the vacuum jacket (external), which ensures vacuum tightness

- multilayer cryogenic insulation

- spacer insulation elements

- moisture sorbent

- thermal shrinkage compensation elements

Design and benefits

![]() High vacuum in the space between the pipes eliminates the inflow of heat through convection.

High vacuum in the space between the pipes eliminates the inflow of heat through convection.

![]()

Sufficient number of MLI layers minimises the inflow of heat through radiation.

![]() Combination of the vacuum technology with multi-layer insulation guarantees the lowest possible inflow of heat to the transported medium. The most efficient insulation available on the market.

Combination of the vacuum technology with multi-layer insulation guarantees the lowest possible inflow of heat to the transported medium. The most efficient insulation available on the market.

![]()

Small vacuum jacket diameter compared with traditional insulation.

![]()

Stainless steel external pipe, which is a vacuum jacket, remains at ambient temperature, providing excellent protection against cold burns.

![]() Stainless steel process pipe designed to work in high

Stainless steel process pipe designed to work in high

hygiene areas.

![]() Option to easily regenerate vacuum.

Option to easily regenerate vacuum.